We are again benefited with another installment by Dr. Bob Hardage on the history of Vertical Seismic Processing (VSP) in the U.S. and the former U.S.S.R. If you have not followed the series, Dr. Hardage has been sharing the history of the introduction of VSP in the U.S. In the ’70s, Dr. Hardage, who was at Phillips at the time, was aware of Dr. Evsey Gal’perin’s work on VSP at the Soviet Academy of Sciences. In a seminal meeting sponsored by Phillips Petroleum in Bartlesville, OK, Dr. Hardage hosted Dr. Gal’perin on his first visit to the U.S. to introduce VSP to the U.S. oil and gas industry. In today’s post (Part 3), he compares the differences between his work at Phillips and that of Dr. Evsey Gal’perin in the Soviet Union. Those of you in the seismic acquisition business will particularly appreciate this nostalgic view of the industry. Please enjoy!

There were stark differences between the way that VSP data acquisition was practiced in Russia versus in the U.S. Gal’perin worked in wells that were drilled strictly for purposes of collecting VSP data, and he could work at a slow measured pace for weeks to collect data. In contrast, I had to utilize wells that were drilled for production purposes and was forced to work around the clock at a frantic pace so I could release the well to engineers who had to do production tests and proceed with well completion. Acquiring VSP data is much like giving birth to babies. The event requires long night-time labor and often occurs on weekends.

Gal’perin worked in isolated areas where he could use buried-explosive sources and could position shot holes wherever he wanted them to be. I worked inside drilling areas and used vertical-vibrator sources. Buried explosives are not so welcome close to producing wells and surface production facilities. My vibrator stations could be positioned only where they would be prescribed distances from surrounding wells, storage tanks, flow lines, and electrical lines.

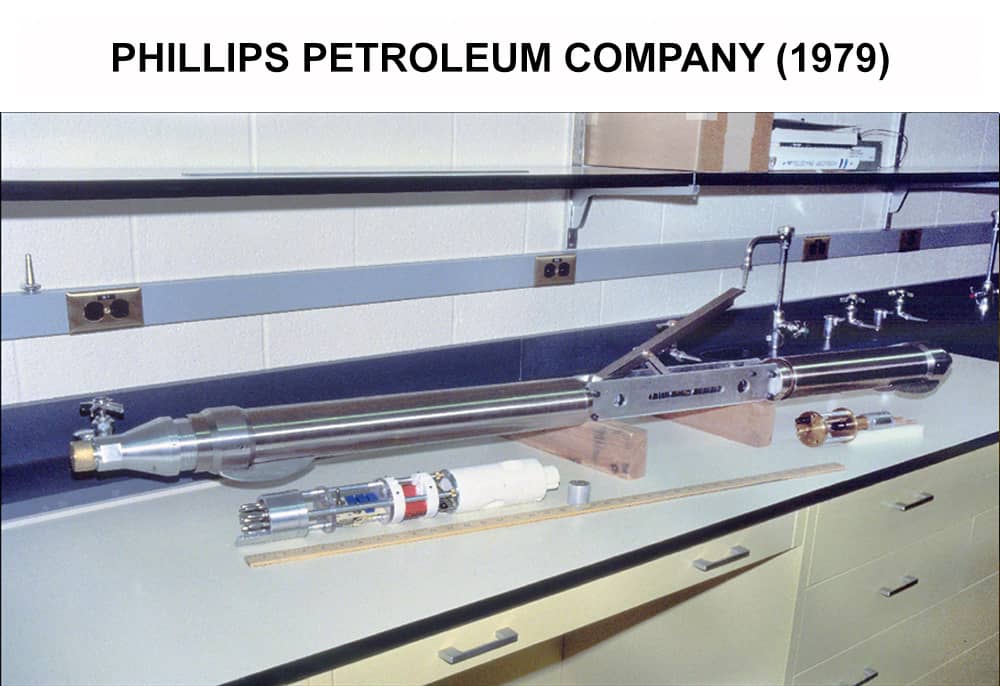

I recognized that my major weakness was ignorance of proper VSP field procedures. Evsey had 25 years of field experience, and I asked him many questions about VSP equipment and field practice. He taught me that downhole receiver packages needed to be as small as practical, and that they should be locked at depth stations with a strong lateral force. I knew immediately that there were no appropriate down-hole VSP geophone packages in the U.S.

The only down-hole geophones available to me were those used to acquire velocity check-shot data. These geophones were thick-walled, stainless-steel tubes, about 10-ft long, that locked in place with a lateral force that could barely hold them in place. They contained only vertical geophones. Later studies showed these check-shot tools had internal resonances between 15 and 60 Hz that distorted VSP reflection wavelets. Any seismic event that passed by a wall-locked check-shot tool introduced false resonances into VSP data.

We at Phillips immediately launched a project to build a proper down-hole VSP geophone. Our new package weighed 40-lbs and was about 4-ft long. We called our tool “the casing cruncher” because the locking arm generated such a large locking force. The tool had 3-C geophones from day-one. Left and right stand-offs on the backside of the tool combined with the locking-arm contact to form three points of contact around the circumference of a well casing that eliminated tool rotation. The improvement in 3-C data quality was spectacular. Thanks to Gal’perin, we at Phillips quickly had a proper down-hole tool for recording VSP data.

Word spread about our VSP receiver development. Engineers from several companies visited us to discuss this new geophone concept. One start-up company at Stanford copied our design, made some modifications, and produced an excellent VSP geophone tool. This company, and their VSP tool concepts, were purchased by Western Geophysical. When I later managed the Downhole Seismic Services Division of WesternAtlas, all of my global VSP crews used tools that were direct descendants of the tool we built at Phillips. The 1979 information exchange I had with Gal’perin had profound effects on VSP data-acquisition in the U.S.

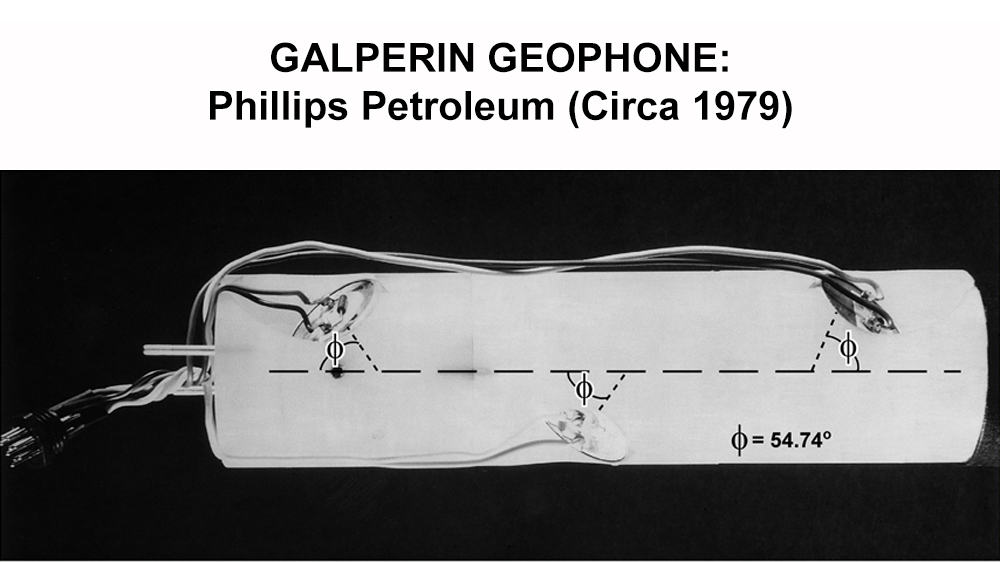

Gal’perin used a unique configuration of geophones to record 3-C VSP data. Rather than installing X-Y-Z geophones, he positioned 3 geophones at horizontal azimuth intervals of 120 degrees and then tilted each geophone upward 54.47-degrees from vertical. When the outputs of these 3 geophones were summed, the horizontal response was zero, and the vertical response was the same as that of a single vertical geophone. This unique geophone configuration became known as a “Gal’perin geophone”.

Gal’perin used this type of geophone geometry because he had no capability to do digital recording and analysis. In order to quality control his analog data during acquisition, he compared the sum of these 3 tilted geophones with the response of a single, vertical geophone also located in his down-hole receiver package. When the summed response of the tilted geophones differed from the single-geophone response, he knew he had distortion in his 3-C data and could search for the cause. The responses of his 3 tilted geophones could be converted to the responses of 3 orthogonal X-Y-Z geophones by mathematical transformation of coordinate axes.

Gal’perin geophones were a short-time fad in the U.S. One company made a surface-based version that used Gal’perin’s 3 tilted geophones. Industry had no interest in the concept. At Phillips, we had two geophone modules we could interchange in our VSP receiver package. One module used Gal’perin’s geophone geometry; the other used a standard X-Y-Z geometry. We found no advantage in Gal’perin’s configuration and continued our VSP work with X-Y-Z geophones. The Gal’perin geophone is, however, evidence of the genius that Gal’perin used to optimize VSP data quality when he had no access to digital data recording.

I think the most important information I obtained from Gal’perin was how to construct proper down-hole VSP geophones. We in the U.S. were able to stand on Gal’perin’s shoulders and get a fast start in building our VSP receivers.

Bob A. Hardage

Bob A. Hardage received a PhD in physics from Oklahoma State University. His thesis work focused on high-velocity micro-meteoroid impact on space vehicles, which required trips to Goddard Space Flight Center to do finite-difference modeling on dedicated computers. Upon completing his university studies, he worked at Phillips Petroleum Company for 23 years and was Exploration Manager for Asia and Latin America when he left Phillips. He moved to WesternAtlas and worked 3 years as Vice President of Geophysical Development and Marketing. He then established a multicomponent seismic research laboratory at the Bureau of Economic Geology and served The University of Texas at Austin as a Senior Research Scientist for 28 years. He has published books on VSP, cross-well profiling, seismic stratigraphy, and multicomponent seismic technology. He was the first person to serve 6 years on the Board of Directors of the Society of Exploration Geophysicists (SEG). His Board service was as SEG Editor (2 years), followed by 1-year terms as First VP, President Elect, President, and Past President. SEG has awarded him a Special Commendation, Life Membership, and Honorary Membership. He wrote the AAPG Explorer column on geophysics for 6 years. AAPG honored him with a Distinguished Service award for promoting geophysics among the geological community.